23 Jan 2026

- 10 Comments

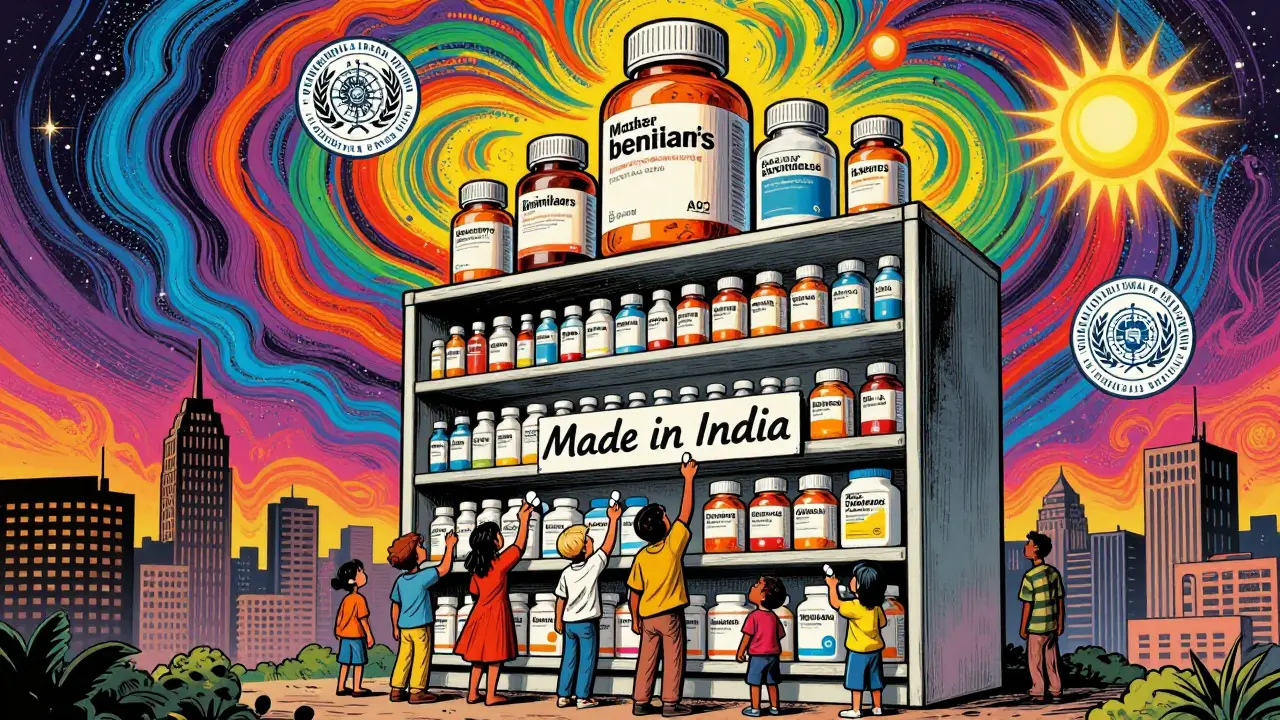

When you take a generic pill for high blood pressure, diabetes, or an infection, there’s a good chance it came from India. The country doesn’t just make medicines-it supplies the world. India produces one in five of all generic drugs shipped globally. It’s the largest vaccine maker on Earth, providing over 60% of the world’s shots. And it does this at prices that make treatment possible for millions who otherwise couldn’t afford it.

How India Became the Pharmacy of the World

It didn’t happen by accident. In the 1970s, India changed its patent laws. Before that, foreign drug companies held exclusive rights to sell their medicines in India. After the change, Indian manufacturers could legally copy any patented drug as long as they made it using a different process. This opened the floodgates. Companies like Cipla and Dr. Reddy’s started making versions of expensive HIV drugs, cancer treatments, and antibiotics at a fraction of the cost. By the early 2000s, this strategy had turned India into a global force. While the U.S. and Europe focused on developing new drugs, India mastered the art of making old ones cheaply and well. Today, it has over 10,000 manufacturing units and more than 3,000 pharmaceutical companies. Of those, 650 are approved by the U.S. FDA-the most outside the U.S. itself. Another 2,000 meet WHO-GMP standards. That’s not luck. It’s infrastructure built over decades.What Kinds of Drugs Does India Make?

Indian factories don’t just churn out simple tablets. They produce complex medicines that require advanced technology: extended-release capsules that last all day, injectables that must be sterile to the last drop, transdermal patches that deliver drugs through the skin. They make generics for heart disease, diabetes, mental health disorders, cancer, and even rare diseases. One of the biggest shifts in recent years has been toward biosimilars-copies of expensive biologic drugs like those used for rheumatoid arthritis or cancer. Companies like Biocon and Dr. Reddy’s have spent billions to enter this space. In 2020, biosimilars made up just 3% of India’s export value. By 2024, that number jumped to 8%. These aren’t just cheaper versions-they’re scientifically complex products that require deep expertise. India also produces over 500 active pharmaceutical ingredients (APIs), the raw chemical building blocks of medicines. But here’s the catch: about 70% of those APIs still come from China. That’s a vulnerability. When global supply chains got disrupted during the pandemic, Indian drugmakers felt the pinch. Now, the government is spending $400 million to fix it. The goal? To make 53% of APIs domestically by 2026.Who Buys Indian Generic Drugs?

The answer is almost everyone. In the United States, Indian companies supply 40% of all generic prescriptions. That’s nearly half of the $100 billion U.S. generics market by volume. In the UK, Indian-made drugs make up 33% of NHS prescriptions. In Sub-Saharan Africa, where public health budgets are tight, Indian generics account for about half of all medicines used. Doctors Without Borders has said Indian-sourced antimalarials and antibiotics cut treatment costs by 65% without losing effectiveness. Even in wealthier countries, patients choose Indian generics because they’re affordable. A 30-day supply of a generic blood pressure pill might cost $5 in the U.S. if it’s made in India. The same drug made in Germany or the U.S. could cost $20 or more. For people paying out of pocket, that difference is life-changing.

Quality Concerns and Misconceptions

There’s a myth that cheap means unsafe. That’s not true. The FDA inspects Indian plants just like it does American ones. In 2015, only 60% of Indian facilities passed FDA inspections. By 2024, that number was 85-90%. That’s on par with global averages. Still, problems happen. A few bad batches have made headlines. In 2023, a Reddit thread about inconsistent dissolution rates in Indian-made levothyroxine (a thyroid drug) got over 140 upvotes. Some users reported taste differences or packaging issues. But these are exceptions-not the rule. The real issue isn’t quality control-it’s consistency across thousands of suppliers. Not every small manufacturer has the same resources as Sun Pharma or Cipla. That’s why regulators keep a close eye. And why the Indian government is tightening rules. In early 2024, new manufacturing standards (Schedule M) came into effect, requiring better documentation, testing, and traceability.Why India Beats China and Europe on Generics

China makes cheaper APIs, but it doesn’t have the same track record of meeting Western regulatory standards. It has only 153 FDA-approved plants compared to India’s 650. European generics makers like Teva and Sandoz make high-quality drugs, but they’re expensive. Their business model relies on brand loyalty and patents. India’s edge? Cost + compliance. It can make a generic drug for 30-80% less than Western competitors and still pass FDA audits. That’s why U.S. pharmacies, hospitals, and insurers rely on it. Even after the U.S. removed tariff exemptions for Indian goods in 2019, imports didn’t drop. Demand stayed strong because there’s no better alternative.

The Road Ahead: From Volume to Value

India exports over $20 billion in pharmaceuticals every year. But it only captures about 10% of the global generics market by value. Why? Because it sells mostly low-cost, high-volume drugs. The real money is in complex generics, biosimilars, and eventually, new drug discovery. That’s why the government launched Pharma Vision 2047-to reach $190 billion in exports by 2047. That’s not just about making more pills. It’s about making better ones. Companies are investing billions in R&D. Sun Pharma spends 6-8% of its revenue on innovation. Biocon is building biologics factories that rival those in the U.S. and Switzerland. The goal isn’t to replace Western pharma. It’s to compete with it. To go from being the world’s pharmacy to becoming its innovation partner.What This Means for Patients

If you take a generic drug, you’re already benefiting from India’s system. It’s not just about price. It’s about access. Millions in low-income countries get life-saving medicines because Indian manufacturers exist. Without them, HIV treatment would still cost $10,000 a year. Cancer drugs would be out of reach for most. Even in wealthy nations, Indian generics keep healthcare costs down. They allow insurers to cover more people. They let governments stretch limited budgets. They give individuals choices. Yes, there are risks. Supply chain delays. Packaging errors. The occasional bad batch. But the system works. And it keeps getting better. The next time you pick up a generic prescription, check the label. If it says ‘Made in India,’ you’re holding a piece of global health equity. And that’s not just a business success story. It’s a medical one.Are Indian generic drugs safe to take?

Yes, most are. Over 650 Indian drug factories are approved by the U.S. FDA, and more than 2,000 meet WHO-GMP standards. Compliance rates have jumped from 60% in 2015 to 85-90% today-matching global averages. While isolated quality issues have occurred, they’re rare compared to the billions of safe doses produced every year.

Why are Indian generic drugs so much cheaper?

India doesn’t allow product patents on drugs, so companies can legally copy branded medicines. They avoid the massive R&D costs that U.S. and European firms pay to develop new drugs. Instead, they focus on efficient manufacturing, lower labor costs, and high-volume production. This lets them sell the same medicine for 30-80% less.

Does the U.S. rely on Indian generic drugs?

Yes. Indian manufacturers supply about 40% of all generic prescriptions filled in the U.S.-that’s nearly half of the market. They make common drugs like metformin, lisinopril, and amoxicillin, as well as complex ones like insulin and cancer treatments. The FDA inspects Indian plants regularly and continues to approve them at high rates.

What percentage of the world’s vaccines come from India?

India produces over 60% of the world’s vaccines by volume. It’s the largest vaccine manufacturer on Earth, supplying everything from polio and measles shots to COVID-19 doses. Companies like Serum Institute of India and Bharat Biotech have played key roles in global immunization programs, especially in low-income countries.

Is India trying to reduce its dependence on China for drug ingredients?

Yes. India imports about 70% of its active pharmaceutical ingredients (APIs) from China. To reduce this risk, the government launched a $400 million Production Linked Incentive (PLI) scheme in 2020. The goal is to boost domestic API production and reach 53% self-sufficiency by 2026. Several new API plants are already under construction across Gujarat and Telangana.

Marlon Mentolaroc

January 25, 2026Man I just checked my last prescription and yep - Made in India. Honestly thought it was from Germany or something. Turns out my $5 blood pressure pill is keeping the global healthcare system from collapsing. Wild.

Gina Beard

January 26, 2026Access is justice. And India quietly built a system where medicine isn’t a privilege - just a product.

Don Foster

January 27, 2026Look the FDA approves these plants but come on you think a lab in Gujarat can match the precision of a Swiss facility I mean really

siva lingam

January 28, 2026India makes 60% of the world’s vaccines and still can’t fix potholes. Priorities amirite?

Shanta Blank

January 28, 2026Let me get this straight - the same country that gives us $1 insulin is also the one where your Uber driver will hand you a chai and a half-burnt samosa while your phone dies. It’s chaos with a pharmacy license and I’m here for it.

Himanshu Singh

January 29, 2026Bro this is the real MVP of global health. No hype, no patents, just millions of pills going to people who’d otherwise die. Keep going, India 🙌

Jamie Hooper

January 30, 2026Went to me GP last week and she said ‘this one’s from India’ - I nearly cried. Like… I’m not paying £20 for a paracetamol anymore. Thank you, thank you, thank you.

Husain Atther

January 31, 2026The rise of Indian pharmaceuticals is not merely an economic phenomenon - it is a moral one. Where profit-driven systems failed, scalable compassion succeeded. This is not luck. It is intention.

Izzy Hadala

February 2, 2026Could you please provide a breakdown of the FDA inspection failure rates by region within India, as well as the correlation between API sourcing volatility and batch recall frequency between 2018 and 2024? The data would be invaluable for risk modeling.

Shelby Marcel

February 3, 2026wait so my thyroid med that tastes like burnt plastic is from india?? 😭